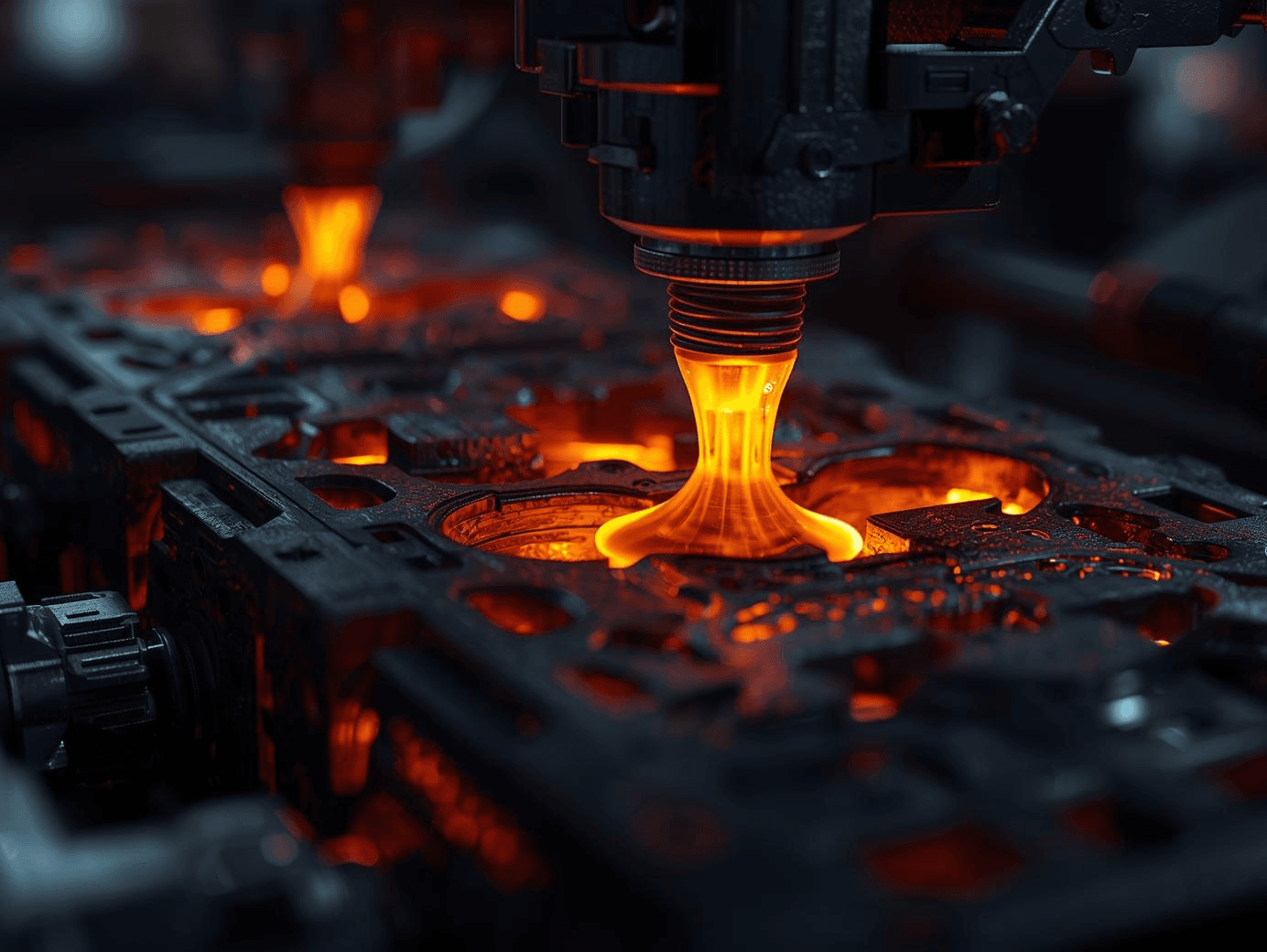

Injection Moulding Service

At Warning Machines, we offer a comprehensive and fully integrated injection moulding service that takes your project from initial consultation through to the delivery of production-ready components. Rather than simply producing parts, we act as a trusted manufacturing partner to product developers, OEMs and industrial innovators. Our focus is on manufacturing plastic and silicone components with exceptional repeatability, precise tolerances and consistent surface finishes, no matter the production scale. By combining our engineering expertise with rapid tooling capabilities and efficient production workflows, we provide a seamless service that allows clients to move from concept to finished product faster and with greater confidence.

Engineering and Design for Manufacturability

Every successful moulding project begins with smart design decisions. We engage with your team early in the development process to ensure that manufacturability is built into your design from day one. Our engineers perform detailed reviews covering wall-thickness analysis, draft and undercut considerations, material compatibility checks and mould-flow simulation. This proactive approach helps to uncover potential risks and bottlenecks at the CAD stage, reducing costly tooling changes later on and accelerating the path to a working mould. By making targeted design suggestions—such as ways to reduce cycle time, minimise material stress, or extend part longevity—we help you achieve both technical excellence and cost-effective production.

Tooling and Prototype Development

The right tool is at the heart of every quality moulded part. Whether your project calls for an aluminum rapid-tooling mould to validate an early concept or a hardened steel production tool for long-run durability, Warning Machines offers both in-house machining and partnerships with trusted toolmakers who meet our rigorous standards. Our rapid prototype tooling allows you to test form, fit and function before committing to large-scale production. Once the prototype is validated, we handle the smooth transition to production-grade tooling, ramping up capacity while maintaining the same tight tolerances and surface finishes you approved in testing.

Material Expertise and Selection

Material choice can make or break the performance of a moulded component. We work with a broad portfolio of engineering-grade thermoplastics and silicones, including ABS, polycarbonate, nylon, TPE, custom elastomeric silicones and a wide array of specialty resins. By analysing factors such as mechanical load, thermal cycling, chemical resistance, cosmetic finish and long-term durability, our team can recommend the best material for your specific application. Because we maintain strong relationships with leading resin suppliers, we can also guide you through regulatory and functional requirements to ensure that your parts perform reliably in real-world conditions.

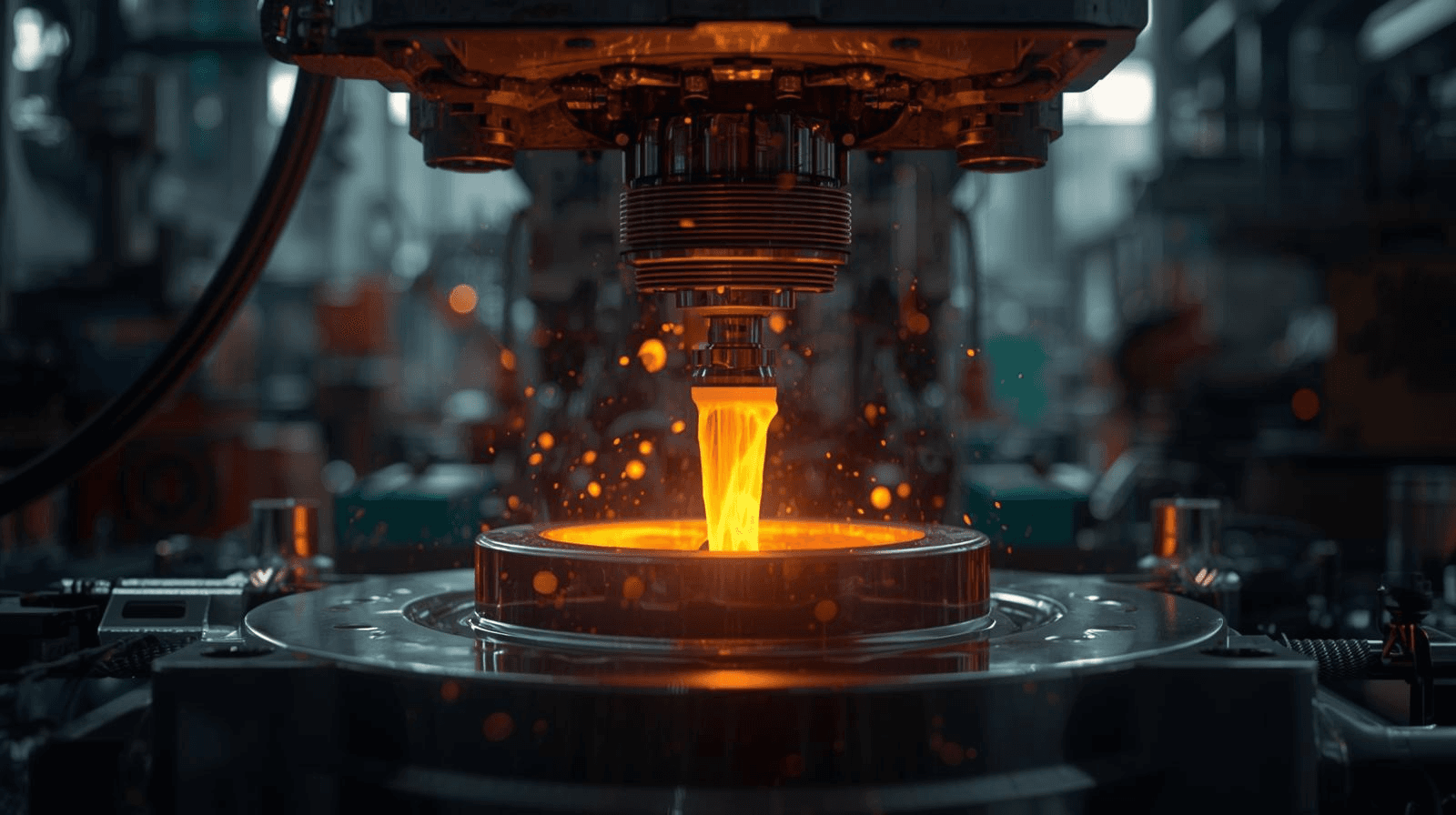

Production Efficiency and Scalability

Our production facilities are equipped with modern injection moulding machines, automated process monitoring systems and disciplined setup procedures designed to deliver consistent quality from the first shot to the last. Whether you need prototype quantities, low- to mid-volume runs or full high-volume production, we tailor our workflows to match your requirements. By emphasising repeatability, tight process control and minimisation of scrap, we keep costs under control while safeguarding surface finish, dimensional stability and material performance as your volumes scale.

Secondary Services and Turnkey Delivery

Beyond moulding, we offer a full suite of secondary services to streamline your supply chain. Our capabilities include part cleaning, trimming, snap-fit assembly, insert moulding, overmoulding, quality inspections and custom packaging. By delivering components that are already cleaned, finished and ready for integration into your final product, we reduce the need for additional in-house processing or complex assembly steps. This turnkey approach helps you shorten lead times, simplify logistics and focus on your core business.