In the modern product development landscape, prototyping plays a pivotal role in validating design concepts, testing functionality, and attracting investment. Choosing the right prototyping technology can significantly impact project timelines, costs, and the quality of the final product. For companies in the United States and the European Union, understanding the strengths and limitations of CNC machining and 3D printing is crucial for making informed decisions.

Warning Machines offers comprehensive prototyping services that combine CNC machining, 3D printing, PCB assembly, and firmware testing under one roof. This integrated approach allows clients to benefit from the advantages of both technologies, ensuring their prototypes meet their exact specifications and functional requirements.

What Is Prototyping?

Prototyping involves creating a preliminary version of a product to test and refine its design. This process can range from simple concept models to fully functional devices. Depending on the product’s complexity and intended use, different manufacturing technologies may be appropriate.

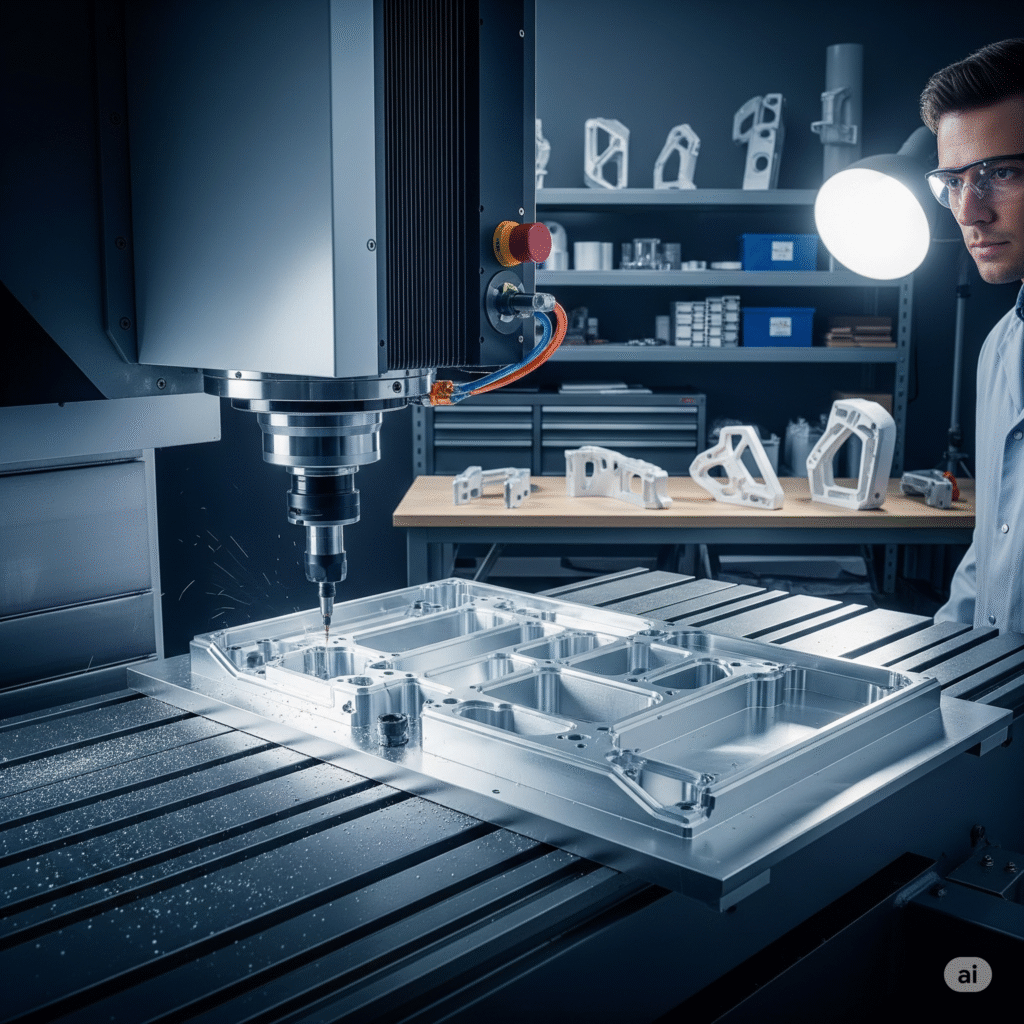

CNC Machining for Prototyping

CNC machining is the gold standard when it comes to creating high-precision, functional prototypes. By removing material from solid blocks, CNC machines produce parts with excellent surface finish and mechanical properties. These parts can be tested under real-world conditions, allowing engineers to validate the design before committing to mass production.

Advantages of CNC prototyping include:

- Tight tolerances and high repeatability.

- Compatibility with a wide range of materials, including metals and engineering plastics.

- Suitable for functional testing and regulatory compliance.

However, CNC machining may involve longer setup times and higher costs for one-off parts compared to additive manufacturing.

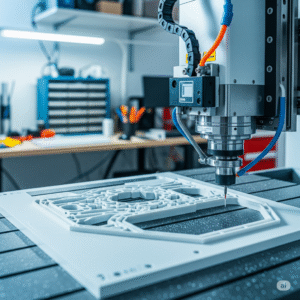

3D Printing for Prototyping

3D printing, or additive manufacturing, builds parts layer by layer based on digital models. It excels at producing complex geometries that are difficult to machine and allows for rapid iterations at relatively low cost.

Common 3D printing techniques include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). These methods mostly work with plastics and resins, making them ideal for concept models and early design validation.

CNC Machining vs. 3D Printing: A Comparative Look

| Aspect | CNC Machining | 3D Printing |

| Precision | High (±0.01 mm), suitable for functional parts | Moderate, varies with technology |

| Material Options | Metals, plastics, composites | Mainly plastics and resins |

| Speed | Longer setup, faster batch runs | Rapid prototyping, especially one-offs |

| Cost | Higher upfront, cost-effective for small runs | Lower for initial prototypes |

| Surface Finish | Smooth, ready for assembly or use | May require post-processing |

Why Warning Machines Is Your Best Prototyping Partner

Warning Machines provides expert guidance to select the right technology based on your prototype’s requirements. Their full suite of services includes:

- CNC machining for high-precision, functional prototypes.

- Advanced 3D printing for rapid and cost-effective concept models.

- Complete electronics integration with PCB assembly and firmware testing.

- Fast Design for Manufacturability (DfM) reviews within 24 hours.

Choosing the right prototyping method is crucial for reducing development risks, optimizing costs, and ensuring your final product meets market expectations. CNC machining remains the best option for high-precision, functional parts that require durability and compliance with strict industry standards, while 3D printing excels in early-stage concept models where speed and cost-effectiveness are priorities.

However, the most successful product development strategies often combine both technologies. By integrating CNC machining for critical components and 3D printing for quick iterations, companies can shorten time-to-market and test their designs more effectively.

At Warning Machines, we specialize in providing this hybrid approach. Our in-house team delivers high-quality CNC machined parts, advanced 3D printed models, PCB assembly, and firmware testing — all within a single production line. This integrated service guarantees consistency, confidentiality, and rapid turnaround, helping businesses in the United States and the European Union launch products faster and with greater confidence.

If you are ready to bring your prototype to life, contact Warning Machines today. Our experts will help you choose the best manufacturing solution for your project and ensure you receive a fully functional prototype in 30 days or less.

Check more about our services on the next link!