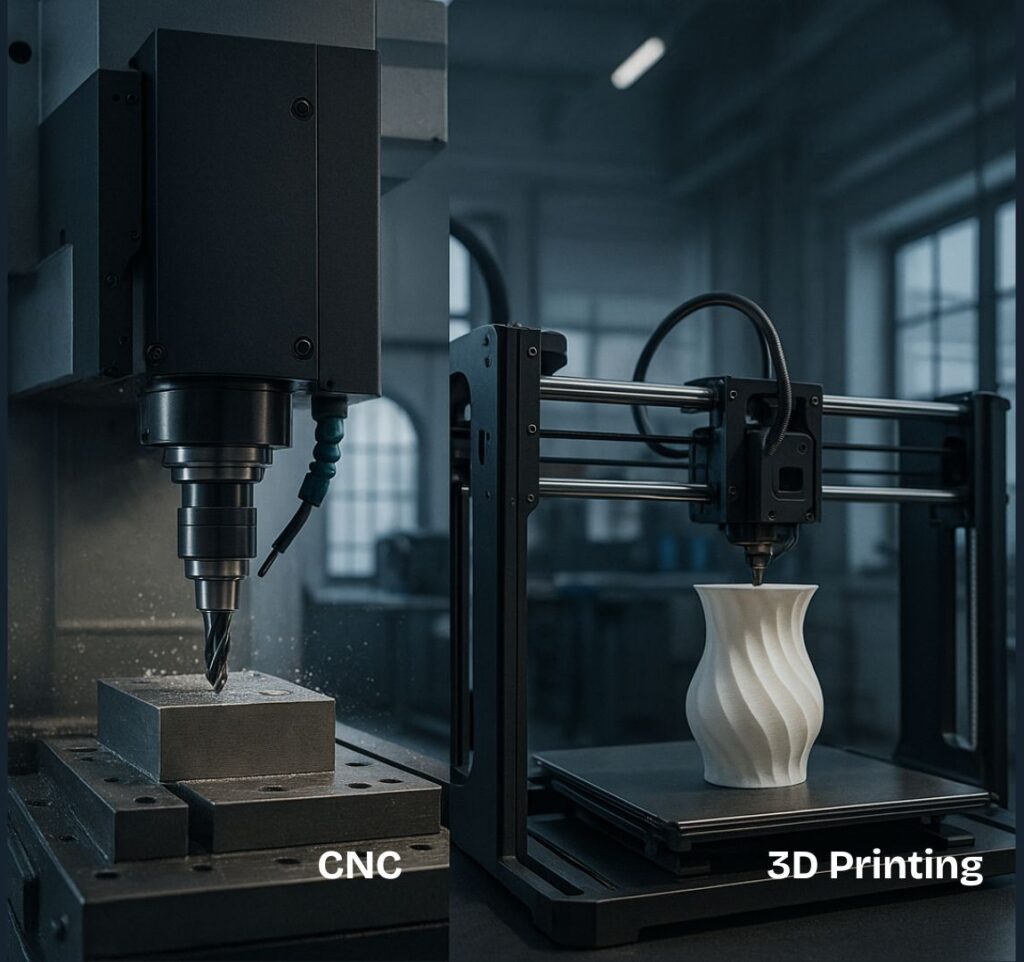

Choosing the proper method for prototyping can directly impact how quickly and efficiently your product reaches the market. CNC machines and 3D printers are two of the most widely used technologies in modern product development, particularly for startups and tech-forward teams. Each brings a unique set of capabilities and constraints to the table. In this guide, we’ll break down how both approaches compare regarding speed, materials, precision, and cost, helping decision-makers choose the most effective tool for each phase of the prototyping process.

Comparing Production Speed

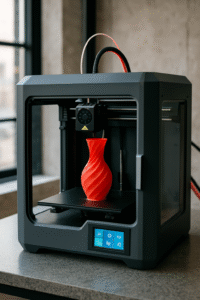

Both CNC machines and 3D printers offer quick turnaround options. 3D printing, particularly FDM or SLA, can produce visual models in just a few hours, making it ideal for early-stage brainstorming, internal design reviews, and aesthetic validation. However, CNC processes often deliver superior speed when producing parts that require machining from common stock materials and can turn around functional parts in under than 72 hours, often faster if the part is simple or uses readily available materials.

For teams under pressure to validate mechanical properties or finalize fit and assembly, CNC’s production speed often beats 3D printing for critical components.

Material Capabilities

Material range is one of the main differences between these two approaches. 3D printers are mostly restricted to using plastics: PLA, ABS, PETG, or resins, but in more advanced applications, they use composite filaments or certain types of metals. These can, however, not be used at all times in mechanical testing as they do not have enough strength and durability. On the other hand, CNC machines can operate on a much broader range of tough materials. Standard materials are aluminum, stainless steel, brass, titanium, and engineering plastics such as PEEK and Delrin. Such materials serve practical purposes and are prototypes of industrial applications attained in aerospace, automotive, and industrial design.

This makes CNC a more suitable option for engineering validation and early functional testing. You’re not only testing form, you’re testing actual function under mechanical stress.

Surface Finish and Precision

When surface quality matters, CNC machining often wins for its superior precision and finish. It offers tight tolerances (as low as ±0.001″), allowing for accurate, repeatable part production. CNC surface finishes are generally clean and smooth, often production-grade. In comparison, most 3D-printed parts require sanding or coating to smooth out layer lines, and the dimensional tolerances are less predictable.

Cost Considerations

3D printers are cheaper for visual prototypes, rough prototypes, early-stage mockups, and prototypes that are merely visual. They are suitable for single-use items since little to no setup cost is involved. Nevertheless, as soon as durability and functionality are concerned, CNC becomes more cost-efficient since there are fewer iterations and greater accuracy. It also does not require any post-processing, taking up time and money.

Use Case Scenarios

- Use 3D Printers When:

- You need fast, low-fidelity visual prototypes

- Testing ergonomic form or aesthetics

- Creating early-stage internal models for stakeholder approval

➡️Learn more about 3D Printing

- Use CNC Machines When:

- You need durable prototypes for real-world stress testing

- Producing precision parts for assembly

- Working with metal or heat-resistant plastics

➡️Learn more about CNC Machining

Although 3D printers perform well when time and visual prototypes are crucial, CNC machining is the machine on which one would go to create reproductions of the part that replicate real-world performance. Product managers, founders, or the R&D leads who already have an idea of when to apply which method can drastically increase the iteration velocity and product stability.

📩 Need help deciding between CNC machines and 3D printers for your next project? Book a consultation with us to get expert guidance.