From Vision to Victory: How to Build Your Idea with Warning Machines?

Introduction

Have you ever had a brilliant idea for a product but felt lost on how to bring it to life? You’re not alone. Many aspiring inventors and entrepreneurs face challenges like where to start, who to turn to for help, and how to manage costs. The journey from concept to market-ready product is complex, but with the right partner, it’s entirely achievable. Warning Machines, a rapid prototyping and manufacturing leader, offers the expertise and services needed to transform your vision into a tangible product. This guide walks you through building your idea, highlighting how Warning Machines can support you every step of the way.

What is the Product Development Journey?

Turning an idea into a product involves several key stages. Understanding these steps can help you navigate the process with confidence:

-

Concept Validation: Confirming your idea is viable and meets a market need.

-

Design and Prototyping: Creating detailed designs and physical prototypes to test your concept.

-

Testing and Iteration: Evaluating prototypes and refining the design based on feedback.

-

Manufacturing: Producing the final product, whether in small or large quantities.

-

Launch and Marketing: Bringing your product to market and reaching your target audience.

Each stage requires specific skills, resources, and expertise, where Warning Machines excels.

How Warning Machines Can Help Me Build My Idea

Warning Machines specializes in turning innovative ideas into high-quality, physical products with speed and precision. Their comprehensive services cover various industries, including electronics, medical devices, and industrial equipment. Below, we explore how our expertise aligns with each stage of product development.

1. Who can validate my Concept before I Build My Idea

Before investing time and money, it’s critical to validate your idea. This involves assessing market demand, technical feasibility, and potential challenges. While you may conduct initial market research yourself, Warning Machines can provide expert insights into the technical aspects of your concept. Our engineers can evaluate whether your idea can be transformed into a functional product and offer suggestions to enhance its viability. This early collaboration helps lay a solid foundation for your project.

2. Design and Prototyping

The design and prototyping phase is where your idea takes physical form. Warning Machines offers a suite of services to create and test prototypes efficiently:

-

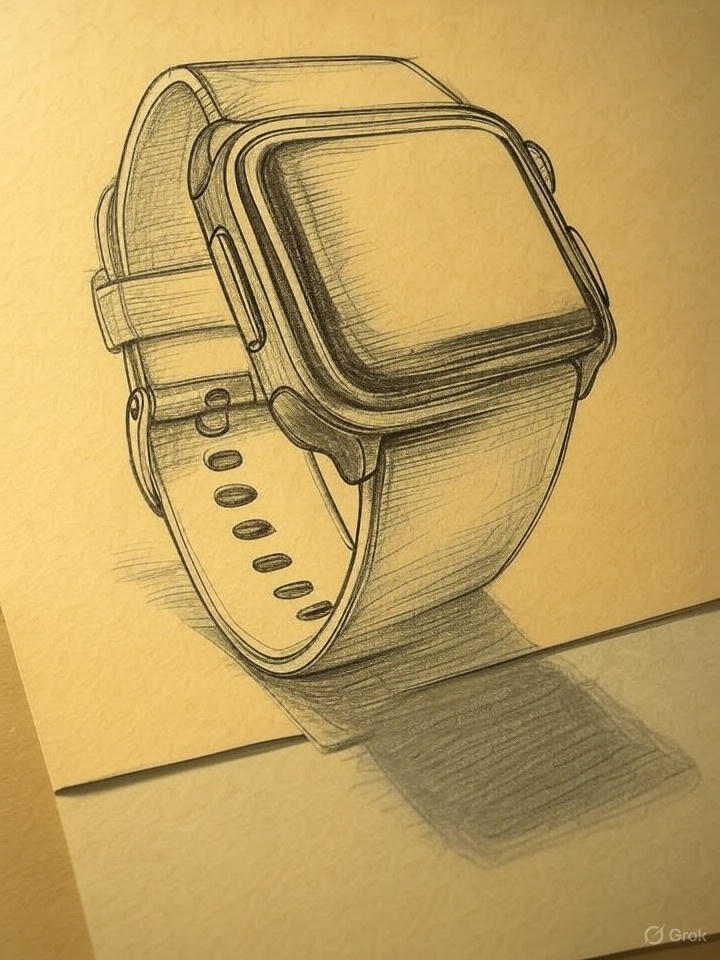

Rapid Prototyping: Using advanced technologies like 3D printing and precision CNC machining, Warning Machines can quickly produce physical models of your product. This allows you to visualize and test your design early in the process, identifying any issues before moving forward.

-

Custom PCB Development: Printed circuit boards (PCBs) are often the heart of electronic product design. Warning Machines handles the entire PCB development process, from initial design to assembly, ensuring your electronics function as intended.

-

Electronics Assembly: Beyond PCBs, Warning Machines can integrate electronic components into your prototype, creating fully functional models ready for testing.

-

Precision CNC Machining: Their CNC machining services deliver prototypes that meet exact specifications for parts requiring high accuracy or specific materials.

These services enable rapid iteration, allowing you to refine your design based on real-world feedback.

3. Testing and Iteration

Once you have a prototype, testing is essential to ensure it performs as expected. Warning Machines supports this phase by offering fast turnaround times for prototype modifications. Our team can quickly produce updated prototypes to validate changes if testing reveals issues such as design flaws or material incompatibilities. This iterative process is crucial for perfecting your product before production.

4. Manufacturing and Build My Idea

When your design is finalized, it’s time to produce your product. Warning Machines offers low-volume manufacturing services, ideal for startups, inventors, or anyone looking to test the market without committing to large production runs. Their manufacturing capabilities include:

-

Low-Volume Molding: For plastic parts, Warning Machines uses low-volume molds and printed jigs to produce small batches efficiently, reducing costs and lead times.

-

Scalable Production: As demand grows, they can transition your product to larger production runs, ensuring scalability without sacrificing quality.

-

Electronics Assembly: We provide end-to-end assembly services for electronic products, ensuring your product is market-ready.

This flexibility lets you start small and scale up as your product gains traction.

5. Launch and Marketing after I Build My Idea

While Warning Machines primarily focuses on the technical aspects of product development, we can also provide guidance on preparing your product for market. This includes ensuring compliance with industry standards and regulations, which is critical for a successful launch. While marketing and sales strategies are typically your responsibility, their expertise can help ensure your product is ready to meet customer expectations.

How can I consider costs before I Build My Idea?

One of the most common questions for aspiring inventors is, “How much will it cost to build my idea?” The answer depends on several factors, including:

-

Complexity: More intricate designs, especially those involving electronics or specialized materials, are more expensive.

-

Materials: The choice of materials for prototypes and production impacts costs.

-

Production Volume: Low-volume manufacturing is generally more cost-effective for initial runs, while large-scale production may require higher upfront investment.

-

Development Stage: Costs vary depending on whether you need only prototyping or full-scale manufacturing.

While exact costs are project-specific, Warning Machines helps manage expenses in several ways:

-

End-to-End Services: By offering design, prototyping, and manufacturing under one roof, they reduce the need for multiple vendors, saving time and money.

-

Expert Guidance: Their experienced team can identify cost-saving opportunities, such as choosing alternative materials or optimizing designs for manufacturability.

-

Low-Volume Manufacturing: Starting with small batches allows you to test the market without significant upfront costs.

To get a precise estimate, you can request a quote from Warning Machines, detailing your project’s requirements.

Who Can Help Me Build My Idea?

Navigating the product development process requires a team of skilled professionals. Warning Machines employs a team of engineers, designers, and manufacturing specialists who are dedicated to bringing your idea to life. Whether you’re developing a smart device, a medical product, or industrial equipment, their expertise spans various industries. They work closely with you to understand your vision, provide technical insights, and deliver high-quality results.

Protecting Your Idea

A common concern for inventors is protecting their intellectual property (IP). While Warning Machines focuses on technical development, it’s worth noting a few steps you can take to safeguard your idea:

-

Document Everything: Keep detailed records of your idea, including sketches, notes, and development progress. This can serve as evidence if you pursue a patent.

-

Non-Disclosure Agreements (NDAs): When working with partners like Warning Machines, consider using NDAs to protect sensitive information.

-

Patents: Consult a patent attorney to explore whether your product qualifies for a patent. However, avoid rushing into costly patents before validating your idea.

Warning Machines respects your IP and works with you to keep your project confidential.

Why Choose Warning Machines?

Warning Machines stands out as a trusted partner for several reasons:

-

Comprehensive Services: We offer end-to-end solutions from rapid prototyping to low-volume manufacturing.

-

Industry Expertise: Our experience spans electronics, medical devices, and industrial equipment, ensuring your project is in capable hands.

-

Speed and Precision: our use of advanced technologies like CNC machining and 3D printing ensures fast, high-quality results.

-

Scalability: We can scale to meet your needs, whether you need one prototype or thousands of units.

Warning Machines’ Services and Their Role in Product Development

|

Service |

Description |

Stage of Development |

|---|---|---|

|

Rapid Prototyping |

Quick creation of physical models using 3D printing and CNC machining. |

Design and Prototyping |

|

Custom PCB Development |

Design and assembly of printed circuit boards for electronic products. |

Design and Prototyping |

|

Precision CNC Machining |

High-accuracy machining for custom parts in various materials. |

Design and Prototyping |

|

Electronics Assembly |

Integration of electronic components into functional prototypes or products. |

Prototyping and Manufacturing |

|

Low-Volume Manufacturing |

Production of small batches using low-volume molds and scalable processes. |

Manufacturing |

Conclusion

Transforming an idea into a product is a challenging but rewarding journey. With Warning Machines as your partner, you gain access to the tools, expertise, and services needed to bring your vision to life. From rapid prototyping to low-volume manufacturing, their team is equipped to guide you through every stage of the process. Don’t let uncertainty hold you back. Start building your idea today.